Shenzhen’s Smart Factories: Where Robotics and AI Work Together

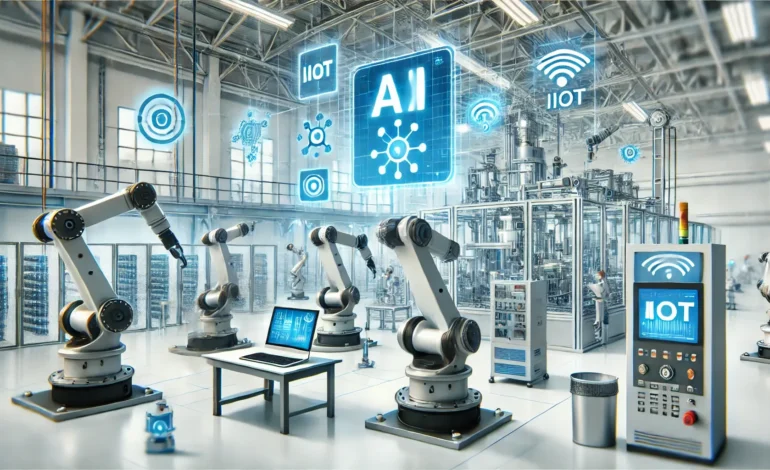

In 2025, Shenzhen has become a global model for industrial transformation through the integration of robotics and artificial intelligence. Once known for its massive labor-intensive manufacturing base, the city is now home to thousands of AI-powered smart factories producing electronics, semiconductors, and consumer goods with minimal human intervention. These factories represent the next stage of China’s Made in China 2025 strategy, where automation, data analytics, and machine learning form the backbone of industrial competitiveness.

The Rise of the AI-Driven Manufacturing Ecosystem

The shift toward intelligent manufacturing in Shenzhen is part of a broader national initiative to upgrade China’s industrial value chain. According to SCMP, local authorities have partnered with leading tech firms to transform traditional production clusters into digital ecosystems powered by AI, robotics, and 5G connectivity.

Manufacturers now deploy AI algorithms that optimize energy use, predict equipment maintenance, and coordinate robotic arms in real time. Reuters reports that over 70 percent of major Shenzhen factories have adopted cloud-based industrial control systems connected to national digital infrastructure networks. This high-tech integration enables continuous monitoring, predictive analytics, and remote decision-making across entire production lines.

Industrial Robots Take the Lead

The expansion of industrial robotics has been crucial to Shenzhen’s productivity boom. Companies such as DJI, Foxconn, and BYD have implemented collaborative robots (cobots) that can safely operate alongside human workers. These cobots perform repetitive assembly, packaging, and inspection tasks with precision and speed.

Nikkei Asia highlights that automation has reduced product defect rates by more than 25 percent while increasing output by nearly 40 percent in certain sectors. Machine learning allows these robots to improve their performance over time by learning from operational data, making them more efficient than static production systems. This integration of AI and robotics has turned Shenzhen into one of the world’s most automated manufacturing zones.

Policy Support and Technological Infrastructure

Government policy continues to play a decisive role in Shenzhen’s smart factory expansion. The Ministry of Industry and Information Technology (MIIT) has established “AI Manufacturing Pilot Zones” where enterprises receive tax incentives and access to national AI data platforms. These policies encourage small and medium-sized enterprises to adopt intelligent systems that would otherwise be financially out of reach.

CGTN reports that Shenzhen’s municipal government has invested heavily in 5G-enabled industrial parks where sensors, robots, and cloud networks operate under unified control systems. This creates a seamless digital ecosystem that links every part of the production cycle from supply chains to end-user delivery.

Human-Machine Collaboration and Workforce Evolution

Despite fears of automation replacing human labor, Shenzhen’s experience demonstrates a more nuanced outcome. While routine jobs are declining, demand for skilled technicians, data analysts, and AI engineers is rising. Bloomberg notes that over 200,000 workers in Shenzhen have been retrained through vocational AI programs supported by major tech companies.

This workforce transition ensures that humans remain essential in managing, programming, and supervising robotic operations. Rather than replacing labor entirely, automation in Shenzhen is augmenting it shifting the city’s labor force from manual assembly to digital innovation.

Sustainability and Global Impact

The integration of AI and robotics also supports China’s environmental goals. Intelligent production lines use predictive algorithms to reduce energy waste and recycle materials more efficiently. According to The Diplomat, factories powered by renewable energy now account for nearly one-third of Shenzhen’s manufacturing capacity. Smart automation helps manufacturers track emissions and resource usage, aligning with national carbon reduction targets.

Internationally, Shenzhen’s success story is influencing manufacturing strategies across Southeast Asia and Europe. Countries seeking to modernize their factories are studying China’s model of AI-industrial synergy, where government policy, private innovation, and infrastructure investment combine to deliver scalable results.

Conclusion

Shenzhen’s transformation into a hub of smart manufacturing illustrates how robotics and AI can redefine industrial efficiency. By merging data-driven decision-making with automation, the city has set a global benchmark for intelligent production. The collaboration between machines and humans is no longer futuristic it is already happening in the world’s most advanced industrial clusters. As China continues to scale this model nationwide, Shenzhen stands as the blueprint for the next generation of sustainable and automated manufacturing.