Industrial Robots Surge: Shenzhen Factories Run 80% Automated Floors

Factories across Shenzhen, China’s manufacturing capital, are transforming into highly automated production zones where robots now perform nearly 80% of repetitive industrial work. This shift marks a decisive step in the country’s strategy to offset labor shortages, boost productivity, and reposition itself as a leader in intelligent manufacturing. Driven by government incentives and rapid advances in robotics, the rise of smart factories is redefining China’s industrial landscape.

The New Face of Manufacturing

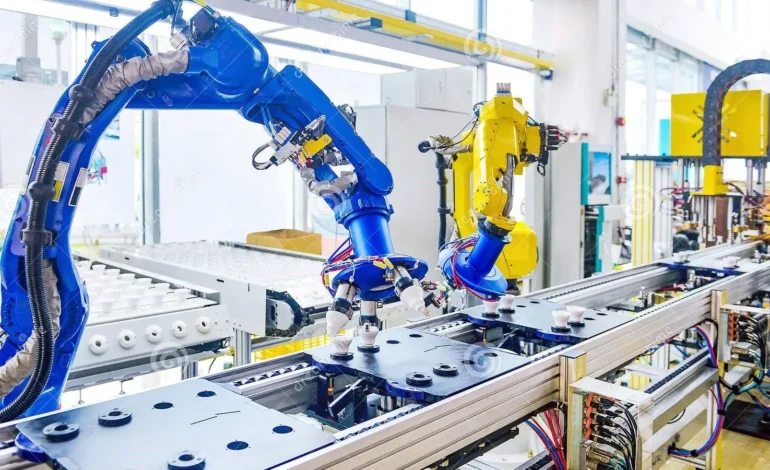

In 2025, Shenzhen’s robotics deployment surpassed every major global manufacturing hub, according to the China Robotics Industry Alliance (CRIA). More than 250,000 industrial robots were installed across electronics, automotive, and precision machinery factories. At BYD’s auto assembly plants, AI-enabled robotic arms handle welding, painting, and inspection with near-zero defect rates. Meanwhile, Foxconn’s Shenzhen complex uses robotic lines to assemble smartphones, circuit boards, and battery packs with minimal human oversight.

Unlike the early automation waves of the 2010s, these systems are fully integrated through AI-driven predictive maintenance, computer vision quality control, and digital twin simulations that replicate every factory process in a virtual environment. Each production floor is linked to centralized cloud dashboards that monitor efficiency and machine health in real time.

The result is a manufacturing model that operates continuously with limited downtime. Factories can run 24 hours a day while reducing production costs by up to 20%.

Policy Support and the Workforce Transition

Shenzhen’s automation boom is backed by policy frameworks introduced under the Made in China 2025 2.0 strategy, which prioritizes advanced manufacturing and smart robotics. The local government provides tax incentives, R&D grants, and land-use benefits to companies investing in automation technologies.

However, policymakers are also addressing the human dimension of automation. More than 300 vocational institutes across Guangdong Province now offer robotics and AI integration training. Programs focus on upskilling factory technicians to become robot maintenance specialists, data analysts, and automation engineers.

According to a report by Nikkei Asia, the transition has created new high-skilled jobs even as routine labor roles decline. Workers who previously performed assembly tasks are being retrained to oversee robotic workflows and analyze operational data. This reorientation of the workforce reflects Beijing’s goal to achieve “innovation-led employment” rather than mass layoffs.

Industrial Robotics and Export Competitiveness

China’s robotics surge is not just about domestic modernization, it is reshaping global trade. Shenzhen-based companies such as Estun Robotics, Efort, and Inovance have begun exporting industrial robots to Southeast Asia, the Middle East, and Europe. These systems compete directly with Japanese and German manufacturers by offering customizable automation at lower costs.

The new generation of Chinese industrial robots is built with advanced sensors, modular joints, and AI adaptability. They can switch between product types without reprogramming, a flexibility crucial for small-batch, high-variation production lines. The export value of China’s robotics industry exceeded $25 billion in 2025, up 34% from the previous year.

Analysts see this as evidence that China is transitioning from being “the world’s factory” to becoming the world’s automation provider, a shift that will redefine industrial competitiveness in the coming decade.

The Broader Economic and Social Impact

The widespread adoption of automation in Shenzhen is transforming economic models across southern China. Productivity gains have boosted the region’s manufacturing output while stabilizing costs in the face of rising wages. Local supply chains have become more resilient, capable of adjusting rapidly to market demand and global disruptions.

At the same time, the city is experimenting with AI-based labor policy planning, using data from robotic production lines to forecast skill gaps and optimize workforce education. This coordination between technology and governance demonstrates how smart manufacturing can be balanced with social stability.

The trend is also influencing China’s broader industrial identity. As domestic robots become export-ready, Shenzhen’s experience is being replicated in Chengdu, Suzhou, and Tianjin, spreading the smart factory model nationwide.

Conclusion

Shenzhen’s 80% factory automation milestone marks a turning point in global manufacturing history. By merging robotics, AI, and digital infrastructure, the city has proven that industrial modernization can coexist with workforce transformation. The success of these automated systems not only enhances China’s productivity but also redefines its role in the global economy from assembly hub to automation innovator.

In the years ahead, Shenzhen’s model is likely to serve as a blueprint for cities seeking to balance efficiency, labor transition, and technological sovereignty in the age of intelligent production.