Human–Machine Integration Defines Future of China’s Industrial Policy

China’s next industrial transformation centers on human–machine integration, a vision where artificial intelligence, robotics, and human expertise converge to create adaptive, intelligent, and resilient production systems. As the nation moves toward Industry 5.0, policymakers are emphasizing a balanced approach that values human creativity alongside automation. This philosophy underpins China’s broader goal of achieving technological sovereignty while maintaining social inclusivity and sustainable growth.

Policy Framework for Industry 5.0

The Ministry of Industry and Information Technology’s strategic roadmap identifies human–machine collaboration as the core principle of future manufacturing policy. Unlike the automation-heavy models of the past, Industry 5.0 prioritizes synergy between cognitive intelligence and human intuition. The framework promotes flexible production systems that integrate robotics, data analytics, and human decision-making. It also establishes national standards for safe interaction between workers and machines, ensuring that technological progress aligns with social and ethical norms.

The Evolution from Automation to Collaboration

China’s industrial base has evolved rapidly through successive phases of mechanization, digitization, and automation. The new phase of collaborative intelligence marks a qualitative shift in how humans and machines interact. Factories are deploying AI systems capable of understanding human gestures, speech, and visual cues to coordinate tasks dynamically. Technicians can reprogram robots through natural language commands or augmented-reality interfaces, allowing for faster customization and reduced downtime. This fusion of physical and cognitive interaction transforms production lines into adaptive ecosystems driven by human insight and machine precision.

Workforce Transformation and Skill Development

The transition toward human–machine integration requires a workforce equipped with multidisciplinary skills. China’s vocational education system is being upgraded to combine robotics engineering, human–computer interaction, and industrial psychology. Universities are introducing specialized courses in cognitive robotics and intelligent manufacturing management. Companies are establishing in-house training academies where workers learn to operate and optimize collaborative systems. This emphasis on education ensures that human capital remains at the center of industrial progress, preventing technological displacement while fostering innovation.

Intelligent Factories and Ethical Design

Human–machine integration also extends to workplace design. Smart factories are being reconfigured to prioritize safety, ergonomics, and cognitive comfort. Collaborative robots are programmed to detect human motion and adjust their speed or trajectory to avoid collisions. AI systems monitor environmental conditions such as lighting and temperature to create optimal working conditions. Ethical guidelines for machine autonomy are being developed to ensure that decision-making processes remain transparent and accountable. This alignment between technology and human welfare defines the essence of China’s Industry 5.0 policy.

Integration Across Sectors

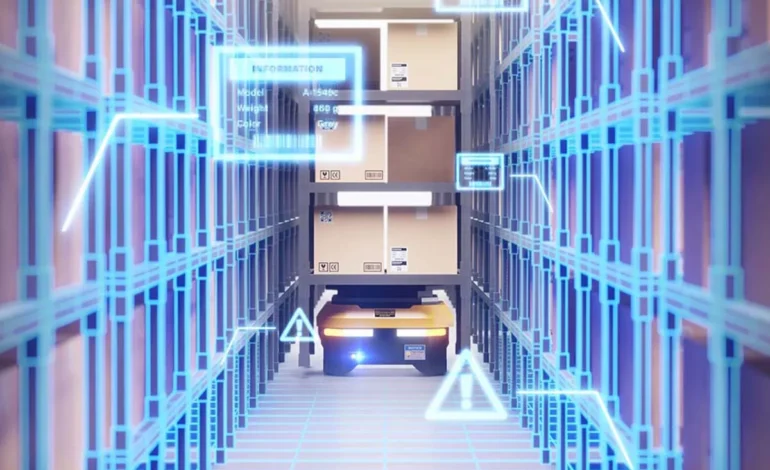

Beyond manufacturing, human–machine integration is reshaping sectors such as healthcare, logistics, and public administration. In hospitals, AI-assisted robotic systems support surgeons and medical staff during complex procedures. In logistics hubs, workers coordinate with automated drones and vehicles through wearable control devices. Government services are also adopting collaborative AI systems that help civil servants manage administrative tasks efficiently. The cross-sector adoption of integrated intelligence demonstrates that China’s approach to automation is comprehensive and human-centered rather than purely mechanistic.

Social Inclusion and Economic Balance

Policymakers view human–machine integration as essential for maintaining social balance amid technological change. By creating new types of jobs focused on system design, supervision, and innovation, the strategy prevents mass unemployment while improving labor quality. Automation is framed not as a replacement for human labor but as an enhancement of human potential. Economic studies show that industries adopting collaborative technologies experience faster productivity growth alongside higher employee satisfaction, reinforcing the policy’s dual focus on efficiency and inclusion.

Collaborative Intelligence

China’s embrace of human–machine integration positions it at the forefront of global industrial evolution. The fusion of robotics, AI, and human adaptability will define the competitive landscape of the next decade. Analysts predict that by 2030, more than half of China’s factories will operate under fully integrated collaborative frameworks. This model exemplifies a shift from machine-driven automation to intelligent cooperation, where technology amplifies human creativity rather than replacing it. The future of China’s industrial policy lies in this balance, achieving progress through partnership between mind and machine.