AI-Powered Cobots Revolutionize China’s Warehouse Efficiency

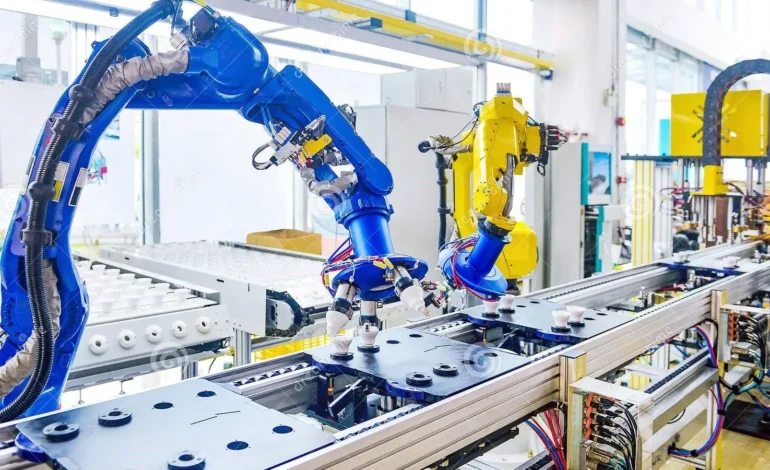

Across China’s logistics hubs and e-commerce fulfillment centers, AI-powered collaborative robots (cobots) are redefining how warehouses function. Designed to work safely alongside human employees, these intelligent machines handle sorting, packaging, and inventory management with speed and precision. As labor costs rise and delivery expectations shorten, cobots are becoming the backbone of China’s logistics automation revolution.

The Evolution of Warehouse Collaboration

Cobots differ from traditional industrial robots in one key aspect: they are designed for human-machine cooperation rather than full replacement. In major logistics centers across Shenzhen, Suzhou, and Hangzhou, cobots equipped with AI sensors and vision systems now assist workers on production lines, handling tasks that require agility and accuracy.

Companies like JD Logistics, Cainiao (Alibaba Group), and Meituan have introduced fleets of cobots capable of lifting, stacking, and sorting thousands of parcels per hour. Each cobot operates through an AI decision-making system that learns from human interactions, continuously improving efficiency and safety.

At JD’s Asia No.1 warehouse in Jiangsu, human workers and cobots share synchronized workflows where robots perform heavy lifting while people focus on quality checks and inventory validation. This partnership model allows warehouses to operate 24 hours a day while reducing physical strain on employees.

AI Integration and Predictive Logistics

The secret behind the success of China’s cobot revolution lies in advanced AI integration. Machine learning algorithms analyze logistics data to predict warehouse bottlenecks, route autonomous vehicles efficiently, and manage inventory flow in real time. Cobots communicate through 5G and industrial Wi-Fi, allowing seamless coordination across multiple warehouse zones.

Huawei’s Smart Logistics Platform combines cobots, AI analytics, and digital twins to monitor operations across an entire supply network. Every robotic movement, from a package scan to pallet transfer, is recorded and optimized through AI feedback loops. These systems have reduced order processing time by up to 40 percent and cut operational errors nearly in half.

At the same time, the use of AI vision systems has enabled cobots to recognize products, identify barcodes, and even assess packaging integrity without human input. This real-time intelligence turns warehouses into responsive ecosystems that self-adjust to demand spikes and changing inventory levels.

Workforce Transformation and Training

As automation expands, China’s labor market is evolving. Rather than eliminating jobs, cobots are changing the skill profile of warehouse work. Workers are now trained to oversee robotic systems, perform software calibration, and interpret data analytics from AI dashboards.

The China Federation of Logistics and Purchasing (CFLP) has partnered with technical universities to create new training modules on AI-based warehouse management. Over 100,000 workers have completed certification programs that qualify them as robotic logistics technicians. These programs ensure that automation adoption goes hand in hand with human skill development.

Companies also report improved job satisfaction, as workers shift from repetitive manual labor to roles involving supervision and problem-solving. This aligns with Beijing’s vision of “human-robot synergy” under the Made in China 2025 2.0 policy framework.

Global Competitiveness and the Future of Automation

China’s mastery of cobot technology is strengthening its position as a global leader in intelligent logistics. Exports of warehouse robotics rose 28 percent in 2025, with Chinese firms supplying systems to Southeast Asia, the Middle East, and Eastern Europe.

Domestic innovators such as Geek+ Robotics, Quicktron, and Hai Robotics have become international competitors, offering modular cobot platforms that can be easily adapted for different industries. Their solutions have attracted foreign investment and established China as a hub for next-generation supply chain automation.

As more nations seek to optimize warehouse efficiency, China’s cobot ecosystem is becoming a model for large-scale, AI-enhanced logistics. With policy support, rapid innovation, and abundant manufacturing capacity, China is poised to lead the next phase of intelligent industrial transformation.

Conclusion

The rise of AI-powered cobots in China’s warehouses demonstrates how automation can empower both industry and labor. By combining robotics, artificial intelligence, and human expertise, China has created a logistics model that is fast, safe, and globally competitive. Cobots are not replacing humans they are redefining work itself, establishing a new standard for smart manufacturing and supply chain excellence.