Beijing’s “AI for Industry” Plan Accelerates Smart Manufacturing 2.0

China is entering the next stage of industrial transformation as Beijing’s “AI for Industry” plan drives a nationwide wave of automation and digital manufacturing. Introduced under the Ministry of Industry and Information Technology’s 2025–2030 roadmap, the program integrates artificial intelligence across production lines, logistics networks, and industrial parks. Its objective is clear: make Chinese manufacturing not only more efficient but also more intelligent, sustainable, and globally competitive.

Policy Framework and National Goals

The “AI for Industry” plan builds on the success of Made in China 2025 and focuses on embedding AI in critical sectors such as automotive, electronics, textiles, and logistics. The government has created more than 40 AI demonstration zones and over 300 intelligent manufacturing pilot factories to serve as testbeds for large-scale deployment. Policies encourage collaboration between cloud providers, robotics firms, and industrial software developers to enable AI-driven decision-making systems that reduce waste and improve precision.

Beijing has also emphasized the role of local governments in funding and adopting AI tools. Provincial authorities in Jiangsu and Guangdong are offering subsidies for smart sensors, predictive maintenance systems, and machine-vision solutions that help factories transition to autonomous production. This aligns with China’s goal of maintaining a 5% annual productivity growth in manufacturing through technology-enabled efficiency.

Industrial Ecosystem and Private-Sector Participation

Leading technology firms have become key drivers of this transformation. Alibaba Cloud and Huawei Cloud are providing AI computing power and industrial Internet platforms, allowing manufacturers to connect production data directly to cloud analytics dashboards. ByteDance’s Volcano Engine is offering real-time anomaly detection and production optimization models that can reduce downtime by up to 30%.

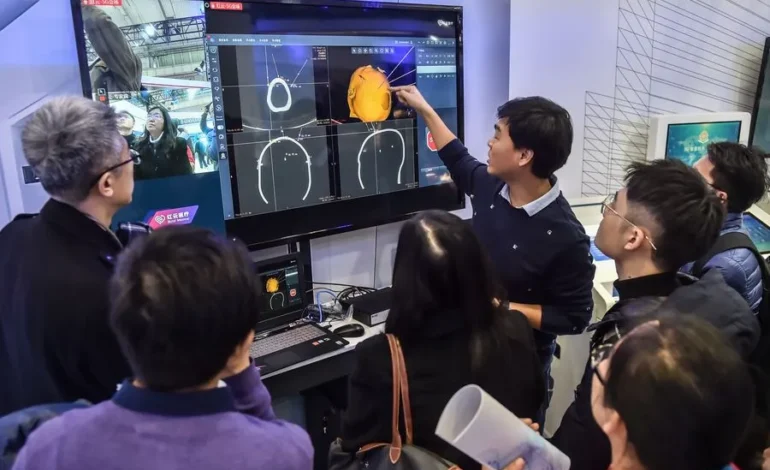

China’s auto and electronics industries are among the biggest beneficiaries. In Shenzhen and Chongqing, factories are now using AI-controlled assembly robots that adapt dynamically to production schedules. Logistics firms are deploying computer-vision sorting systems capable of processing millions of parcels per day, while textile manufacturers in Suzhou have integrated AI-driven quality control to cut defects and material waste.

These developments show a clear shift from single-machine automation to networked industrial intelligence. The new model emphasizes collaboration between machines, sensors, and enterprise AI systems, creating an industrial environment that can respond instantly to changes in demand or supply.

Smart Logistics and Green Manufacturing Synergy

AI integration is also transforming logistics and environmental management. Intelligent route optimization and digital twin simulations are helping companies cut carbon emissions and streamline transportation costs. The Ministry of Transport has integrated the AI for Industry plan into its Green Supply Chain Program, which aims to reduce logistics-related emissions by 15% before 2028.

In ports such as Ningbo-Zhoushan and Qingdao, automated cranes and AI-controlled vehicles now manage cargo operations around the clock with minimal human intervention. Meanwhile, smart energy-management systems in industrial parks monitor real-time energy use, helping factories shift to renewable power when available. This combination of automation and sustainability marks a strategic effort to make China’s manufacturing both eco-efficient and data-driven.

Global Competitiveness and Strategic Outlook

Beijing’s initiative is positioning China as a leader in industrial AI exports. Southeast Asian economies, particularly Vietnam, Indonesia, and Malaysia, are adopting Chinese-built AI solutions for manufacturing optimization. Analysts from Nikkei Asia predict that China’s share in global industrial AI systems could rise from 28% in 2025 to 40% by 2030, driven by affordable, modular solutions that combine AI, IoT, and edge computing.

Conclusion

China’s success in industrial AI depends on continued innovation, international cooperation, and high data reliability. By linking cloud analytics with smart robotics, Beijing’s “AI for Industry” plan provides a model for how developing economies can industrialize without relying on traditional, resource-heavy infrastructure. The transformation is not only about efficiency; it represents a shift toward intelligent production ecosystems that will define the Smart Manufacturing 2.0 era.