Government Support for Local Chip Manufacturing

China’s semiconductor industry has become a strategic priority for national development. By 2025, government support for local chip manufacturing is driving expansion, technological innovation, and global competitiveness. Policies and incentives are designed to encourage domestic fabrication, research and development, workforce development, and industrial clustering. This blog explores the structure of government support, its impact on local chip production, and the broader implications for China’s semiconductor ecosystem.

Policy Framework for Chip Manufacturing

The Chinese government has implemented a comprehensive policy framework to support domestic chip production. Policies include financial subsidies, tax incentives, and grants for research and development. Strategic plans focus on advanced logic, memory, and AI-specific chips. National initiatives prioritize technology self-reliance, supply chain resilience, and industrial modernization. These policies create a favorable environment for domestic fabs, encouraging investment and accelerating production capabilities.

Financial Incentives and Subsidies

Financial incentives play a key role in promoting local chip manufacturing. Subsidies reduce the cost of establishing fabs, procuring advanced equipment, and conducting research. Grants support innovation in lithography, packaging, and materials science. Low-interest loans provide capital for scaling production capacity. By alleviating financial barriers, these incentives enable startups and established manufacturers to invest in high-performance chip fabrication.

Tax Benefits and Regulatory Support

Tax incentives are another component of government support. Reduced corporate income tax rates, exemptions on import duties for key equipment, and favorable depreciation policies lower operational costs for chip manufacturers. Regulatory guidance streamlines approvals for fab construction, environmental compliance, and operational licensing. This combination of fiscal and regulatory support enhances the feasibility and speed of local chip production projects.

Industrial Clusters and Strategic Zones

Government initiatives encourage the development of semiconductor industrial clusters. Regions such as Jiangsu, Shanghai, and Guangdong host clusters that integrate fabs, R&D centers, suppliers, and logistics infrastructure. These clusters foster collaboration, reduce costs, and promote innovation. Strategic zones also provide access to skilled labor, advanced equipment suppliers, and research institutes, strengthening the domestic semiconductor ecosystem.

Research and Development Funding

R&D funding supports technological innovation in chip design, fabrication, and manufacturing processes. Investments focus on advanced process nodes, high-performance logic chips, memory technologies, and AI accelerators. Collaborative projects between universities, research institutes, and fab operators accelerate prototyping, testing, and commercialization. Continuous R&D ensures that domestic chips meet international performance standards and remain competitive in global markets.

Workforce Development Programs

Skilled labor is essential for local chip manufacturing. The government invests in training programs, technical education, and partnerships with universities to develop expertise in lithography, wafer processing, quality control, and AI chip design. Workforce development ensures operational efficiency, high yield, and technological innovation in domestic fabs. By cultivating specialized talent, China strengthens the long-term sustainability and competitiveness of its semiconductor industry.

Infrastructure and Equipment Support

Government support extends to infrastructure and equipment provision. Policies encourage investment in high-quality cleanrooms, utilities, logistics networks, and advanced manufacturing equipment. Domestic production of key materials and photolithography tools is prioritized to reduce dependency on foreign suppliers. Infrastructure and equipment support ensures that fabs can operate efficiently, scale production, and maintain high standards in chip fabrication.

Collaboration and Public-Private Partnerships

Public-private partnerships are encouraged to leverage resources, knowledge, and capabilities. Collaborative initiatives allow domestic manufacturers to share technology, access government research programs, and participate in pilot projects. These partnerships facilitate technology transfer, accelerate production readiness, and strengthen the overall semiconductor ecosystem. Cooperation between government agencies, private companies, and research institutes is a cornerstone of China’s strategy for local chip manufacturing.

Environmental and Sustainability Initiatives

Environmental compliance is integral to government support programs. Policies promote energy-efficient fab design, water recycling, chemical waste management, and emission reduction. Sustainable manufacturing practices ensure that chip production aligns with national environmental goals. Compliance with environmental standards enhances international credibility and enables Chinese fabs to participate in global supply chains while maintaining ecological responsibility.

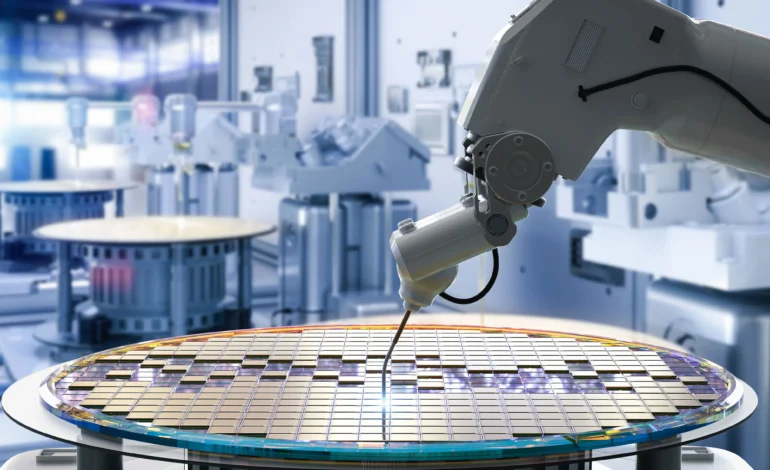

Impact on Domestic Production

Government support has significantly increased domestic chip production capacity. Expanded fabs, improved R&D capabilities, and skilled labor contribute to higher output of logic chips, memory devices, and AI accelerators. By strengthening domestic production, China reduces reliance on imports, improves supply chain resilience, and positions its semiconductor industry for sustainable growth. The combination of financial, regulatory, and strategic support has accelerated the development of a competitive domestic semiconductor ecosystem.

Global Competitiveness and Strategic Significance

Domestic chip manufacturing supported by government initiatives strengthens China’s global competitiveness. By producing high-performance chips locally, China enhances technological independence and secures strategic industries such as AI, automotive, and communications. Local production enables exports, participation in international supply chains, and development of advanced manufacturing capabilities. Government-backed growth ensures that China remains a major player in the global semiconductor market.

Challenges and Ongoing Efforts

Despite strong support, challenges remain, including high capital investment requirements, access to advanced equipment, and skilled workforce shortages. Geopolitical factors may affect technology imports and supply chains. Ongoing government programs focus on equipment innovation, talent development, and supply chain resilience to address these challenges. Continued policy adaptation ensures sustainable growth and competitiveness of local chip manufacturing.

Future Outlook

By 2025 and beyond, government support will continue to play a pivotal role in local chip manufacturing. Expansion of fab capacity, technological innovation, and industrial clustering will enhance domestic production. Integration with AI, 5G, and advanced manufacturing technologies will improve efficiency, yield, and global competitiveness. Continued investment in workforce development, R&D, and infrastructure ensures that China’s semiconductor industry remains technologically self-reliant and strategically significant.

Conclusion

Government support for local chip manufacturing is critical to China’s semiconductor strategy. Through financial incentives, tax benefits, R&D funding, workforce training, and industrial cluster development, China is expanding domestic fabrication capacity and technological capability. These initiatives reduce import dependence, enhance global competitiveness, and secure national strategic interests. By 2025, government-backed local chip manufacturing forms the foundation of a resilient and innovative semiconductor ecosystem, positioning China as a global leader in high-performance and AI chip production.