Next-Gen Fabs and Environmental Standards

The expansion of next-generation semiconductor fabrication plants, or fabs, in China reflects a commitment to both technological advancement and environmental responsibility. By 2025, these next-gen fabs are incorporating cutting-edge processes, automation, and sustainable practices to minimize environmental impact while producing high-performance chips for AI, communications, automotive, and industrial applications. This blog explores the development of next-gen fabs, environmental standards, energy efficiency measures, and the balance between production scale and sustainability.

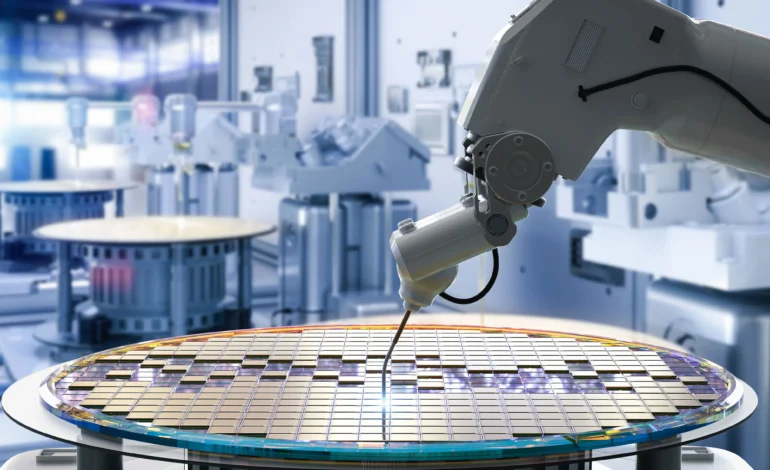

Technological Advancements in Next-Gen Fabs

Next-generation fabs employ advanced process nodes, including 7nm, 5nm, and pilot 3nm technologies, to produce high-performance chips. Automation and robotics streamline production, improve yield, and reduce energy consumption. Advanced lithography, deposition, and etching systems enhance precision and reduce material waste. Next-gen fabs also integrate AI-driven process monitoring and predictive maintenance to optimize production efficiency and ensure consistent quality in semiconductor fabrication.

Environmental Standards and Regulatory Compliance

Environmental standards guide the design, construction, and operation of next-gen fabs. Regulations address energy consumption, water usage, chemical handling, emissions, and waste management. Fabs must comply with national standards for air and water quality, environmental impact assessment, and sustainable manufacturing practices. Compliance ensures safe operation, reduces ecological impact, and aligns with China’s broader environmental and sustainability goals.

Energy Efficiency and Renewable Integration

Next-gen fabs prioritize energy efficiency to reduce carbon footprint. High-efficiency HVAC systems, energy recovery technologies, and smart lighting optimize energy use. Many fabs integrate renewable energy sources, such as solar and wind, to power operations. Energy management systems monitor consumption in real time, enabling optimization of production schedules and reduction of peak demand. These measures ensure sustainable growth while maintaining high-performance manufacturing capabilities.

Water Management and Recycling

Water is a critical resource in semiconductor fabrication, particularly for cleaning and cooling processes. Next-gen fabs implement advanced water treatment, recycling, and conservation technologies. Closed-loop water systems reduce consumption and minimize wastewater discharge. Real-time monitoring ensures water quality and compliance with environmental regulations. Efficient water management supports sustainable operations and reduces environmental impact, which is essential for scaling high-volume fabs responsibly.

Chemical and Waste Management

Semiconductor fabrication involves hazardous chemicals and materials that require careful handling. Next-gen fabs employ strict chemical management protocols, including safe storage, automated dispensing, and waste neutralization. Hazardous waste is treated or recycled to minimize environmental contamination. Process optimization reduces chemical usage without compromising production quality. Comprehensive chemical and waste management ensures safe operation, environmental protection, and regulatory compliance.

Sustainable Materials and Green Manufacturing

Next-gen fabs emphasize the use of environmentally friendly materials and green manufacturing practices. Low-emission materials, energy-efficient components, and recyclable packaging reduce environmental impact. Automation and precision manufacturing minimize material wastage. By integrating sustainability into every stage of production, next-gen fabs demonstrate responsible industrial growth and align with global environmental standards.

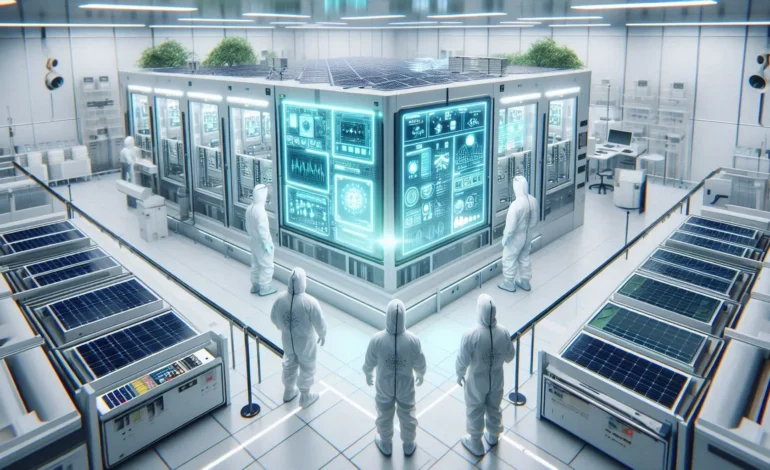

Industrial Clustering and Eco-Friendly Design

Fabs are often part of industrial clusters designed to optimize resource sharing, logistics, and environmental management. Next-gen fabs incorporate eco-friendly design principles, including modular layouts, optimized airflow, and energy-efficient cleanrooms. Clusters allow centralized water treatment, energy distribution, and waste recycling, reducing overall environmental footprint. Industrial clustering supports both operational efficiency and environmental sustainability.

Monitoring and Compliance Systems

Next-gen fabs integrate monitoring systems to ensure continuous compliance with environmental standards. Sensors track energy usage, water consumption, air emissions, and chemical handling in real time. Data analytics identify inefficiencies, predict maintenance needs, and prevent environmental violations. Monitoring systems enable proactive environmental management and support transparent reporting to regulators and stakeholders.

Economic and Strategic Implications

Next-gen fabs contribute to economic growth by supporting high-value chip production and industrial modernization. Sustainable practices reduce operational costs associated with energy and material consumption. Compliance with environmental standards enhances international competitiveness and credibility, enabling fabs to participate in global supply chains. Strategic development of environmentally responsible fabs positions China as a leader in sustainable semiconductor manufacturing.

Challenges in Implementation

Despite technological and environmental advancements, challenges remain. High capital expenditure, integration of renewable energy, water scarcity, and strict regulatory requirements can complicate fab development. Balancing operational efficiency with environmental compliance requires careful planning, continuous monitoring, and investment in sustainable technologies. Ongoing innovation and collaboration with government agencies help overcome these challenges.

Innovation and Industry Collaboration

Next-gen fabs are supported by collaboration among manufacturers, research institutes, and technology providers. Joint research focuses on sustainable materials, energy-efficient process technologies, and smart fab operations. Collaborative pilot projects test environmental initiatives and optimize fab design. Knowledge sharing across the industry accelerates adoption of best practices and promotes continuous improvement in environmental performance.

Future Outlook

By 2025 and beyond, next-gen fabs in China will continue to expand while incorporating sustainable technologies, smart monitoring systems, and energy-efficient operations. Integration with AI, predictive maintenance, and renewable energy will optimize resource usage and environmental impact. Government regulations and industry standards will evolve to further support sustainable fabrication. These initiatives ensure that China’s semiconductor industry grows in both scale and responsibility, producing high-performance chips while minimizing ecological impact.

Conclusion

Next-generation fabs are transforming China’s semiconductor industry by combining advanced manufacturing capabilities with rigorous environmental standards. Energy efficiency, water recycling, chemical management, and sustainable materials are integral to fab operations. Industrial clustering, monitoring systems, and regulatory compliance enhance both production efficiency and ecological responsibility. By 2025, China’s next-gen fabs demonstrate that large-scale semiconductor production can be technologically advanced, economically viable, and environmentally sustainable, positioning the country as a global leader in responsible chip manufacturing.