Smart Warehousing Expands via AI-Enabled Logistics Systems

China’s logistics industry is entering a new phase of digital transformation as AI-enabled warehousing systems reshape how goods are stored, managed, and delivered. With rapid e-commerce growth and rising demand for fast, traceable logistics, smart warehouses powered by artificial intelligence, robotics, and 5G connectivity are becoming essential components of the national supply chain. The expansion of this ecosystem is enhancing efficiency, reducing waste, and setting global benchmarks for intelligent logistics operations.

Evolution of Intelligent Warehousing

Smart warehousing has evolved from basic automation into a fully integrated digital management system. Modern facilities combine AI-driven analytics, autonomous vehicles, and robotic arms to handle sorting, inventory tracking, and packaging. These systems communicate through cloud-based networks, synchronizing every stage of logistics in real time. In China’s industrial hubs such as Hangzhou, Suzhou, and Guangzhou, companies are deploying large-scale intelligent warehouses that can process over one million parcels daily with minimal human intervention. This level of automation allows businesses to meet growing consumer expectations for faster delivery and reliability.

Role of AI in Logistics Optimization

Artificial intelligence is the brain behind China’s new logistics architecture. Algorithms forecast demand, manage inventory levels, and allocate resources based on predictive modeling. Warehouse management platforms use AI to analyze incoming data from e-commerce platforms and shipping systems, dynamically adjusting storage and routing decisions. Machine-vision systems enable robots to recognize and categorize products with precision, while natural language processing allows automated systems to communicate seamlessly with human supervisors. This intelligent coordination reduces operational errors and optimizes every movement within the supply chain.

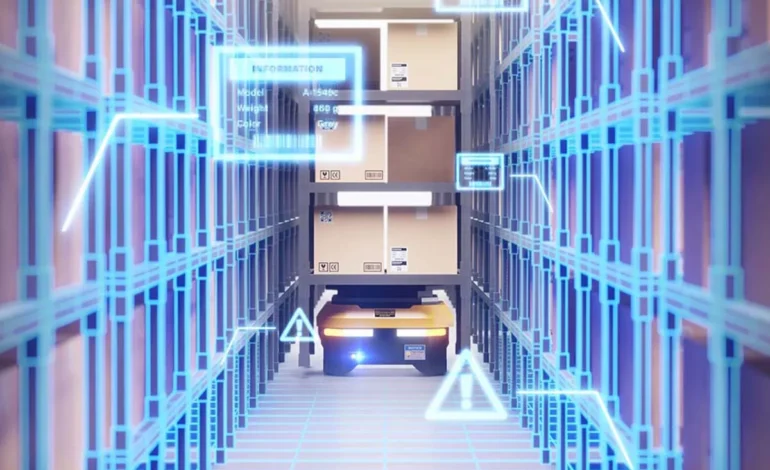

Robotics and Human Collaboration

Smart warehouses are redefining the balance between human workers and machines. Autonomous mobile robots transport pallets, scan barcodes, and replenish stock shelves, while humans handle complex decision-making and quality control. Collaborative robots are equipped with advanced safety sensors that allow them to operate side by side with workers in confined spaces. This human–machine collaboration not only boosts productivity but also reduces physical strain and safety risks. Training programs in logistics and robotics management are expanding nationwide to equip workers with the skills required for this hybrid environment.

Data Connectivity and Real-Time Monitoring

China’s smart warehousing systems are supported by advanced data infrastructure that enables real-time visibility across supply networks. IoT sensors track temperature, humidity, and product movement, ensuring the integrity of sensitive goods such as pharmaceuticals and perishable food. 5G connectivity allows instant communication between devices, enabling rapid response to disruptions. Cloud-based dashboards consolidate this data for managers, providing end-to-end transparency that improves decision-making and supply chain resilience. The ability to visualize inventory flow in real time marks a major leap in logistics efficiency.

Sustainability and Energy Efficiency

Environmental sustainability has become a core element of China’s logistics modernization strategy. Smart warehouses are designed to minimize energy consumption through AI-optimized lighting, automated ventilation, and renewable power integration. Solar panels and energy storage systems supply a growing share of electricity for logistics centers. Predictive analytics identify inefficient energy use and suggest corrective actions. The shift toward green logistics supports China’s carbon neutrality goals while enhancing cost efficiency and brand reputation for companies adopting eco-friendly operations.

E-Commerce Growth and Demand Surge

The expansion of AI logistics systems is closely linked to China’s booming e-commerce sector. Platforms such as JD.com, Alibaba, and Pinduoduo rely on high-speed fulfillment networks to manage billions of transactions annually. During major online shopping festivals, smart warehouses handle unprecedented order volumes without disruptions. AI forecasting enables retailers to position inventory closer to consumers, reducing delivery times and shipping costs. This intelligent distribution model has become the backbone of China’s digital retail economy and a blueprint for global logistics innovation.

The Global Influence of China’s Smart Logistics Model

As Chinese technology firms export their logistics expertise, countries across Asia, the Middle East, and Europe are adopting similar AI-driven warehouse models. Chinese-built logistics parks abroad integrate automation and predictive analytics for regional trade operations. The standardization of software, robotics, and 5G communication protocols allows seamless scalability across borders. Analysts expect China’s smart warehousing technologies to dominate the next wave of global logistics modernization, enabling faster, greener, and more transparent global trade.