Top Fabs Leading AI Chip Production

Artificial intelligence (AI) is transforming industries worldwide, driving demand for specialized high-performance chips. In China, leading semiconductor fabrication plants or fabs are at the forefront of AI chip production. By 2025, domestic fabs are producing advanced logic chips, neural network accelerators, and high-bandwidth memory systems to meet both industrial and commercial AI demands. This blog explores the top fabs contributing to AI chip production, their technological capabilities, industry impact, and strategic significance for China’s semiconductor ecosystem.

Strategic Importance of AI Chip Production

AI chips are critical for powering applications in autonomous vehicles, cloud computing, data centers, robotics, and industrial automation. Domestic production ensures technological self-reliance, reduces dependence on foreign suppliers, and strengthens national security. Fabs leading AI chip production support China’s broader objectives of industrial modernization, technological innovation, and global competitiveness. By focusing on high-performance nodes, AI accelerators, and optimized manufacturing processes, these fabs play a central role in the country’s strategic roadmap.

SMIC: Leading Logic and AI Chip Production

Semiconductor Manufacturing International Corporation (SMIC) is one of China’s largest and most advanced fabs. SMIC focuses on producing high-performance logic chips suitable for AI workloads, including neural network accelerators and inference processors. The company operates advanced 14nm and 7nm process nodes and invests in next-generation lithography and packaging technologies. SMIC’s integration of AI-driven process control and quality management enhances yield, reliability, and efficiency, positioning it as a top AI chip producer in China.

Hua Hong Semiconductor: Specialized AI Production

Hua Hong Semiconductor focuses on specialty processes, including power management chips and AI-specific semiconductors. Its fabs integrate high-purity materials, precise lithography, and advanced wafer processing techniques. Hua Hong’s AI chip production supports both domestic industrial applications and international collaborations. By concentrating on niche high-performance chips, Hua Hong complements other fabs and strengthens China’s overall AI semiconductor capabilities.

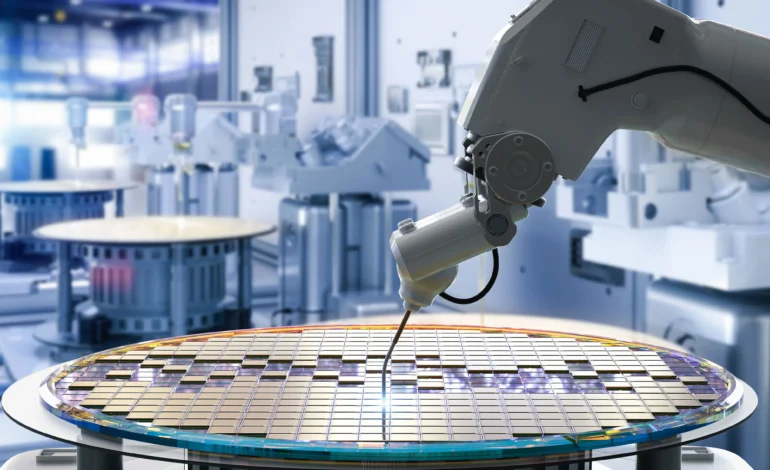

Yangtze Memory Technologies (YMTC) and Memory Solutions

YMTC specializes in NAND flash memory and high-bandwidth storage solutions critical for AI processing. AI applications require large amounts of memory for neural network training and inference. YMTC’s fabs utilize 3D NAND stacking, high-speed interfaces, and optimized fabrication processes to deliver high-capacity, energy-efficient memory chips. By providing domestic alternatives to imported memory, YMTC supports the scalability and reliability of China’s AI ecosystem.

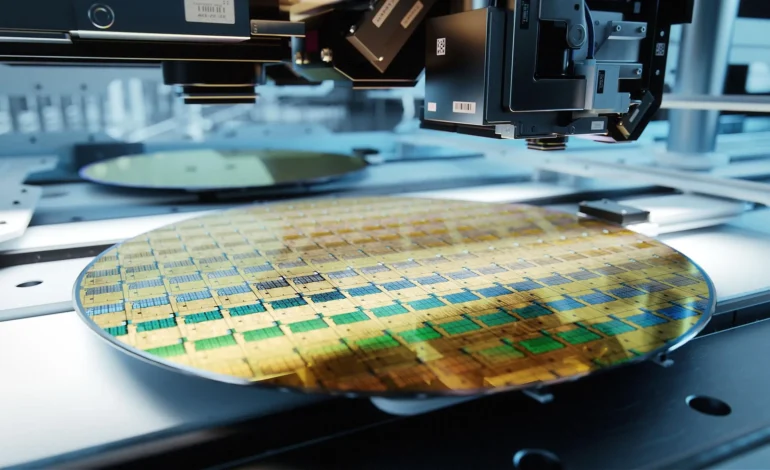

Advanced Packaging and Heterogeneous Integration

Leading AI chip fabs integrate advanced packaging techniques to enhance performance, thermal management, and energy efficiency. Technologies such as chiplet architectures, 2.5D/3D packaging, and high-bandwidth interconnects enable higher throughput and optimized AI computation. Domestic fabs focus on integrating multiple chip components into a single module, reducing latency, improving power efficiency, and supporting complex AI workloads. Advanced packaging differentiates China’s AI chip capabilities in the global market.

R&D and Innovation Ecosystem

Top fabs maintain close collaboration with universities, research institutes, and AI startups to innovate in chip design, materials, and process optimization. Joint research focuses on developing specialized neural processing units, AI accelerators, and energy-efficient architectures. R&D integration accelerates prototyping, testing, and production readiness, ensuring that fabs remain at the cutting edge of AI chip manufacturing. By 2025, continuous innovation enables domestic fabs to meet evolving AI technology requirements.

Industrial Clusters and Supply Chain Integration

AI chip production relies on integrated supply chains within industrial clusters. Fabs are strategically located near suppliers of silicon wafers, photolithography equipment, chemicals, and testing facilities. Proximity to R&D centers, logistics networks, and industrial partners enhances efficiency and scalability. Supply chain integration ensures timely delivery, consistent quality, and the ability to rapidly respond to AI market demands. Industrial clusters amplify the capabilities of individual fabs and strengthen China’s overall AI semiconductor ecosystem.

Talent Development and Workforce Expertise

High-performance AI chip production requires specialized skills in lithography, wafer processing, AI architecture, and quality control. Leading fabs invest in workforce development through training programs, university collaborations, and in-house certification initiatives. A skilled workforce ensures process reliability, high yields, and operational excellence. Talent development is critical for maintaining competitive advantage in AI chip production and sustaining innovation across the fab network.

Government Support and Strategic Funding

Government policies play a pivotal role in supporting AI chip fabs. Incentives include funding for research, infrastructure, process upgrades, and international collaboration. Regulatory frameworks streamline approvals, ensure compliance with environmental and safety standards, and encourage industrial clustering. By providing strategic support, the government facilitates large-scale production, innovation, and technological self-reliance in AI chip manufacturing.

Global Competitiveness and Market Implications

China’s leading AI chip fabs enhance global competitiveness by supplying high-performance processors for domestic and international applications. Advanced logic chips, neural accelerators, and memory modules support AI in automotive, cloud computing, industrial automation, and smart city projects. Domestic production reduces reliance on imported chips, strengthens supply chain resilience, and positions China as a major contributor to the global AI semiconductor market.

Environmental and Sustainability Considerations

AI chip fabs consume significant energy and resources. Leading fabs implement energy-efficient processes, water recycling systems, and emissions controls. Sustainable practices, including waste management and green manufacturing, align with national environmental objectives and international standards. By adopting eco-friendly operations, fabs balance technological advancement with environmental responsibility.

Challenges in AI Chip Production

Despite technological advances, challenges persist. Access to advanced lithography equipment, high-yield production at cutting-edge nodes, and talent shortages remain critical hurdles. Supply chain dependencies and global geopolitical factors impact component sourcing. Leading fabs address these challenges through domestic equipment development, R&D investment, workforce training, and collaborative partnerships with industry and academia.

Future Outlook

By 2025, China’s top AI chip fabs are expected to expand production, adopt next-generation nodes, and integrate advanced packaging solutions. Focus on heterogeneous integration, AI-specific architecture, and energy-efficient processes will enhance performance and market competitiveness. Strategic government support, talent cultivation, and industrial collaboration will continue to drive innovation, positioning China as a global leader in AI semiconductor production.

Conclusion

Top semiconductor fabs in China are driving AI chip production through technological innovation, industrial integration, and strategic investment. Leading players like SMIC, Hua Hong Semiconductor, and YMTC provide advanced logic chips, specialized AI accelerators, and high-bandwidth memory solutions. Combined with workforce development, government support, and supply chain integration, these fabs strengthen China’s domestic AI semiconductor ecosystem. By 2025, China’s AI chip fabs play a central role in global competitiveness, industrial modernization, and technological self-reliance.